I am interested in this product

Close Form

NeuBeam is a truly ground-breaking metal additive manufacturing process that effectively neutralises the electron beam (eBeam) powder bed fusion (PBF) process to offer greater flexibility than laser-based additive manufacturing processes while overcoming the stability issues many users of traditional eBeam additive manufacturing systems experience.

I am interested in this product

Close Form

Downloads

Detailed Specs

Wayland developed and introduced NeuBeam to “neutralise” the problems associated with existing laser and eBeam powder bed fusion (PBF) metal additive manufacturing processes.

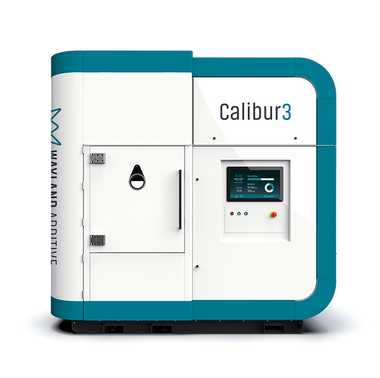

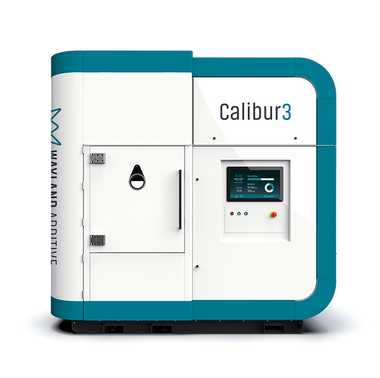

NeuBeam represents a completely new system architecture based on a stable, reliable and flexible electron beam powder bed fusion additive manufacturing process. With NeuBeam additive manufacturing process it is possible to produce fully dense parts in a wide range of materials.

Many of the materials which are not compatible with traditional eBeam or laser PBF processes such as refractory metals and highly reflective alloys can now be processed with NeuBeam.

The NeuBeam process can demonstrate vastly improved metallurgy, without many of the compromises that existing metal additive manufacturing processes necessitate.

NeuBeam is delivered with comprehensive, real-time, in-process monitoring that facilitates full traceability and layer wise quality assurance capabilities.

eBEAM PBF TECHNOLOGY

- Favourable energy transfer

- Sintercake, difficult powder removal

- Long layer times

- High energy consumption

LASER PBF TECHNOLOGY

- Easy powder removal

- High residual stress

- Part size limited by gas flow

- Structural supports

NeuBeam TECHNOLOGY

- Superior Metallurgy

- Low Residual stress

- Easy powder removal

- Favourable energy transfer

- High Productivity