I am interested in this product

Close Form

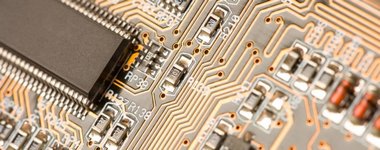

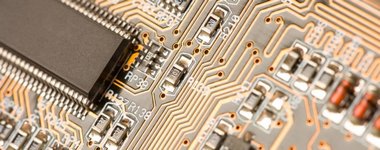

Aerosol Jet based 3D Printed electronics systems reliably produce ultra-fine feature circuitry well beyond the capabilities of thick-film and ink-jet processes. Print die & component attach, underfill and component encapsulation, and 3D interconnects which require feature sizes as small as 10 microns to millimeters can be produced.

I am interested in this product

Close Form

Downloads

Detailed Specs

Materials can be written with a resolution of down to 20 microns. For Ag, 3D Printed Electronic features as small as 10 microns with a 20 micron pitch can be written. This capability offers a solution for the production of smaller, high performance components critical to size-sensitive applications like those in the wireless and hand-held device markets where component density is increasing dramatically.

The ability of the Aerosol Jet based 3D Printed Electronics technology to create fine features with complex geometries in 3D from a wide range of materials makes it suitable for the production of both passive and active components, including resistors, inductors, capacitors, filters, micro-antennae, micro-batteries, and sensors. The precise edge definition and repeatability of the process are particularly relevant to high-frequency requirements. In comparison to screen-printing, embedded resistors can be made smaller and more accurately with the Aerosol Jet electronics 3D printer, such that no laser-trimming is needed to tune the resistor to the right value.

3D Interconnects

- Stacked Die & Other Complex Packaging Applications

- Embedded Passives on Rigid & Flex Substrates

- Component / Die Attach Applications

- Component Underfill and Encapsulation