I am interested in this product

Close Form

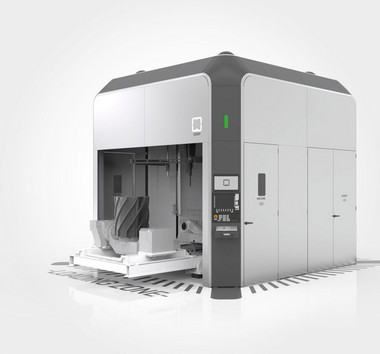

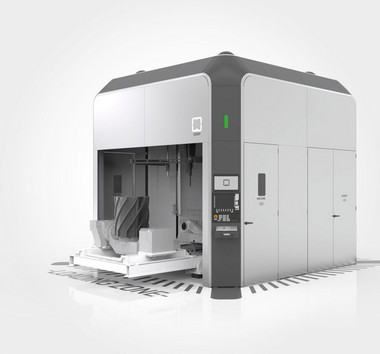

Gefertec GmbH, Berlin, Germany, has introduced its 3DMP® manufacturing technology, a Wire Arc Additive Manufacturing (WAAM) technology which enables the production of parts with qualities comparable to those offered by standard manufacturing methods.

I am interested in this product

Close Form

Downloads

Detailed Specs

3DMP’s Wire Arc Additive Manufacturing process forms the part by welding layer on layer, the wire-based method offers a number of advantages compared to powder-based metal 3D Printing technologies, such as the elimination of powder handling and the significantly lower cost of wire compared to metal powders. In addition, Wire Arc Additive Manufacturing offers significantly higher production speeds of up to 600cm3 per hour, depending on the material.

Gefertech offers 3-axis wire based metal 3D Printing systems for the production of parts up to 3 m³ with a maximum mass of 3000 kg, 5-axis machine for parts up to 0.8 m³ with a maximum mass of 500kg and five-axis system for parts up to 0.06m3 with a maximum mass of 200kg for the production of complex and large parts made of steel, nickel, titanium or aluminium.

Compared to other manufacturing methods, the wire based metal 3D Printing offers maximum material utilisation, resulting in substantial cost savings of up to 60%. This makes the wire based metal 3D Printing technology promising for applications in the aerospace industry and other applications where cost is a major factor, especially when using high-cost materials.